This article introduces the application principle and characteristics of magnetic fluid sealing technology, and points out that the preparation of magnetic fluid with high saturation magnetization and the design of sealing devices with high magnetic field strength are two key elements of magnetic fluid sealing technology.

1. Principle of Magnetic Fluid Sealing

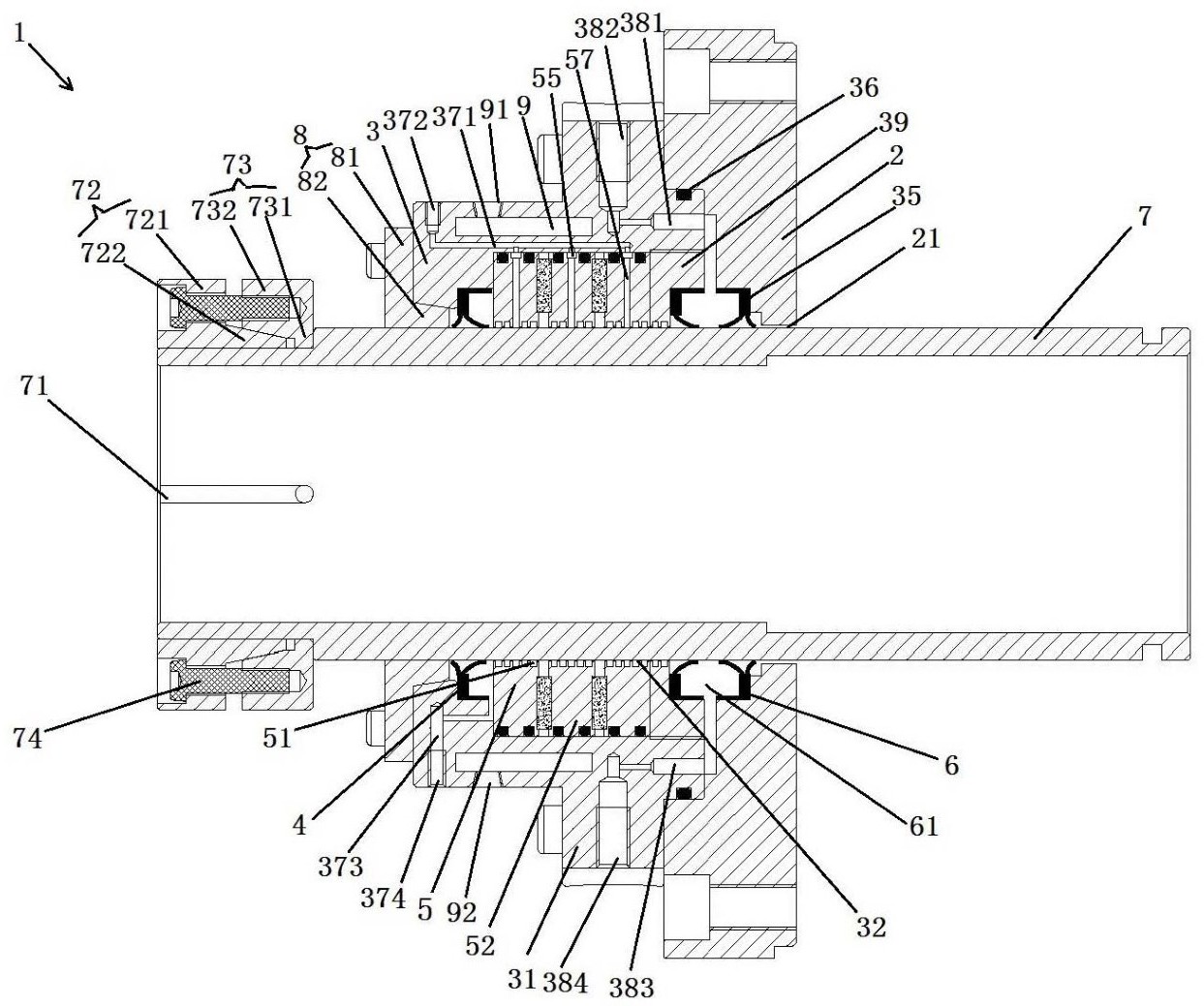

Magnetic fluid sealing technology is a new type of sealing method, which refers to the use of magnetic fluid with high saturation magnetic strength to seal related mechanical equipment. As magnetic fluid itself is a liquid fluid, it has the basic characteristics of a liquid fluid and the magnetism of a magnetic solid material. Magnetic fluid sealing technology is based on the response characteristics of magnetic fluid to magnetic field changes. Figure 1 is a typical schematic diagram of the structure of a device that uses magnetic fluid for sealing. Magnetic fluid sealing mainly consists of two parts, namely magnetic fluid and a specially designed magnetic fluid sealing device. The magnetic fluid sealing device includes a magnetic shaft, magnetic pole, non magnetic seat, bearing, permanent magnet, etc. The design of the magnetic fluid sealing device makes it have a certain magnetic field gap. When the magnetic fluid is injected into the magnetic field gap, Under the action of the magnetic field around the magnetic field gap, due to the liquid fluidity and magnetic effect of the magnetic fluid itself, the magnetic field gap will be filled with magnetic fluid. The annular design of the magnetic field gap will allow the magnetic fluid to form a special "liquid O-ring" in the magnetic field gap. Due to the characteristics of the magnetic fluid itself and the structural design of the sealing device, the O-ring can exist stably, providing a good sealing effect on the sealing medium, The formation of a "liquid O-ring" is not only related to the magnetic properties of the magnetic fluid itself, but also to the strength of the magnetic field gap. Practice has shown that in order to improve the sealing effect and pressure bearing capacity of the entire sealing device, it is necessary to form multiple magnetic circuits in the magnetic fluid sealing structure, namely a multi-stage magnetic fluid sealing structure. There is a pressure difference effect during sealing. When this pressure difference acts on the "liquid O-ring", the magnetic fluid will slightly move. Due to the response of the magnetic fluid to the external magnetic field, The "liquid O-ring" has the characteristic of maintaining and restoring its original state, which generates magnetic force against pressure difference, which is the sealing principle of magnetic fluid.

Schematic diagram of the composition and structure of the magnetic fluid sealing device

2. Characteristics of magnetic fluid sealing

The main purpose of sealing is to protect the working medium and prevent leakage or pollution of the working medium. With the rapid development of industry, sealing plays an increasingly important role in the field of industrial equipment and mechanical manufacturing. Poor sealing can cause leakage of the sealing medium and pollute the environment. At the same time, external impurities invade the equipment and pollute the sealing medium, seriously affecting the normal operation of production, causing huge production waste and economic losses. Static sealing and dynamic sealing are two basic forms of sealing. Static sealing refers to the sealing between relatively stationary parts in mechanical equipment, while dynamic sealing refers to the sealing between relatively moving parts. At present, the traditional sealing method mainly uses rubber parts for sealing, including nitrile rubber, hydrogenated nitrile rubber, silicone rubber, fluorine rubber, etc. Rubber parts are widely used and are currently the most widely used sealing method. However, rubber parts have many disadvantages such as easy expansion and dissolution, easy wear by sealing parts, easy pollution of sealing media, and easy aging. Rubber parts are prone to poor sealing performance due to sealing, Lose sealing performance of sealing equipment.

Compared to traditional sealing defects, magnetic fluid sealing utilizes magnetic force to seal, which has advantages that traditional sealing cannot match. Its main characteristics include the following:

(1) Leakage free sealing: Magnetic fluid is a fluid with high saturation magnetic strength. Currently, the use of high saturation magnetic fluid and well-designed sealing devices can provide a tight and highly stable dynamic or static sealing of the medium, with almost no leakage. The reason is that the magnetic fluid can fill the sealing gap of the entire sealing equipment, forming a "liquid O-ring". At the same time, changing the magnetic field strength of the sealing device will also change the viscosity of the magnetic fluid, thereby strengthening the sealing effect of the magnetic fluid and further reducing the possibility of sealing medium leakage. This characteristic is crucial for sealing corrosive gases as well as toxic, flammable, and explosive gases.

(2) Non wear seal: Traditional contact seals have high friction and wear between contact components, which affects the service life of the seals and the power of mechanical equipment, resulting in significant power loss. Magnetic fluid sealing avoids the generation of debris due to friction between the sealing element and the rotating shaft. At the same time, as an oil-based fluid, magnetic fluid itself also has a lubricating effect, which plays an important role in protecting mechanical equipment components and reducing friction and wear.

(3) Non polluting sealing: Magnetic fluid seals, due to the use of liquid magnetic fluid as the sealing element, do not have friction and wear, and do not generate grinding. At the same time, magnetic fluid has extremely low saturated vapor pressure, which can ensure that even in a vacuum state, it will not cause pollution to the sealing medium. Magnetic fluid seals can effectively avoid external and internal pollution to the sealing medium.

(4) Non directional sealing: The design of the magnetic fluid sealing device allows both sides to withstand different pressures. If the pressure bearing direction of the sealing device needs to be changed, it can be achieved without adding any components to the magnetic fluid. Magnetic fluid sealing has no directionality and is equally effective in preventing external leakage and internal leakage.

(5) Non loss sealing: Magnetic fluid generally uses oily liquid substances as the base fluid. In sealing components equipped with bearings, magnetic fluid itself has minimal internal friction force in the rotating state, low heat generation, and greatly reduces the loss of mechanical power caused by friction of the sealing components. Magnetic fluid sealing power loss is small, so it can also be used for high-speed rotary sealing.

(6) Long life sealing: As a special sealing element, the service life of magnetic fluid sealing mainly depends on the service life of the magnetic fluid. The magnetic fluid itself is a stable fluid, and its effective life can reach 20 years at 40 ° C while maintaining the magnetic fluid characteristics unchanged. And the magnetic fluid sealing structure has a simple construction system and reliable working performance.

(7) Stability sealing: Due to the fluid effect and viscosity change effect of magnetic fluid, magnetic fluid sealing will not cause loss of sealing performance due to instantaneous overvoltage breakdown. During use, even if the sealing device fails due to magnetic fluid, it only needs to be replaced or supplemented with magnetic fluid.