Tooth shaped gaskets are generally made of a certain thickness of metal core (usually stainless steel or other metal or alloy materials), composite with two layers of flexible graphite, polytetrafluoroethylene, asbestos free, mica free, or other high-temperature and corrosion-resistant materials as the surface. They have high strength, low loss of elasticity, and are widely used.

The metal toothed gasket is covered with expanded graphite (or PTFE, or other high-temperature and corrosion-resistant materials) on the sealing surface. The soft sealing layer avoids direct contact between metal and metal, and can reliably and tightly bond. Even under extremely high loads, it can protect the metal flange from damage. The wave tooth combination gasket is particularly suitable for situations with high temperature, high pressure, and alternating working conditions. It is an ideal substitute for traditional metal clad gaskets at the flange connections of heat exchangers, vessels, and reactors. It can be used for high-temperature, high-pressure, and steam pipelines in oil refining, chemical, petrochemical factories, power generation, nuclear power plants, and other industries. It is suitable for flange connection and valve cover connection, and is very suitable for narrow flange connection.

The toothed structure allows the bolt load to concentrate on smaller sealing surfaces and tighten the cover surface at lower torques. The metal core can resist cold flow, excessive compression, and bursting. Even large-sized gaskets have exceptional stability, and they are also easy to handle and install.

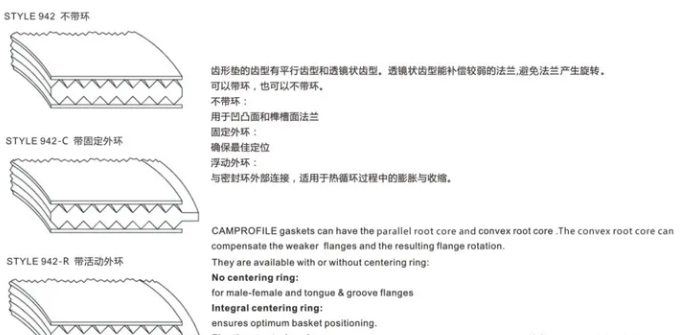

The structural types of this gasket are divided into two basic types depending on the sealing surface of the flange:

Toothed gasket with locating ring for flat flanges

Toothed gasket without locating ring for concave convex flanges

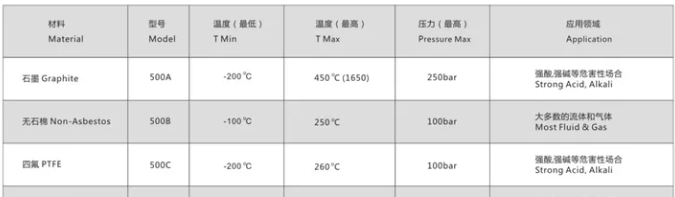

The maximum operating temperature and pressure depend on the surface coating material used for the gasket.

The highest temperature resistance is also the vermiculite metal toothed gasket, which is a combination of toothed metal core and high-temperature vermiculite sealing cover. It is suitable for equipment flange interfaces and has a long service life. Due to the overall metal core being able to withstand a large surface stress, in addition to being resistant to ultra-high temperatures, the overall gasket can also withstand super large bolt action without considering crushing failure. Attention should be paid to issues such as bolt failure and flange deformation caused by excessive bolt pressure.

Vermiculite metal toothed gasket, with a maximum operating temperature of 1000 degrees Celsius and a recommended maximum operating pressure of 300bar. The gasket can directly reach a maximum of 6m or more, and the thickness can be customized according to standards. Ribbed gaskets can be provided with the material and size of the ribs according to demand.

The recommended working conditions are high-temperature and ultra-high temperature working conditions, high-temperature oxygen working conditions, and harsh corrosive working conditions. Suitable for the use of body and connecting pipeline flanges of high-temperature equipment (reactors, regenerators, heat exchangers, pressure vessels, etc.).