Solid metal gasket

Metal ring gasket is a solid metal gasket processed from metal material with a cross-sectional shape of octagonal or elliptical, which has a radial self tightening sealing effect. Therefore, the metal ring gasket is in contact with the inner and outer sides (mainly the outer side) of the flange trapezoidal groove and forms a seal by pressing it tightly.

Chinese name: Metal ring gasket, octagonal or elliptical in shape

Product Introduction

The metal ring gasket originated in the United States and was first used in the boiler field in the 1920s for sealing manhole covers, high-pressure vessels, and other containers. It has been particularly valued in the petroleum production and refining industry since then. With the increase of temperature and pressure in steam power plants, the use of metal ring gaskets has become increasingly widespread. The nominal pressure applicable to metal ring gaskets is 2.0~42.0 MPa

classification

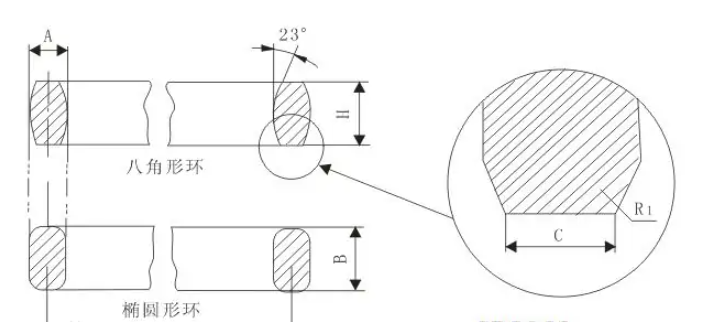

Metal ring gaskets are divided into two types: octagonal ring gaskets and elliptical gaskets. The metal ring gasket can be divided into two structures according to its cross-sectional shape: octagonal and elliptical, as shown in the figure.

The octagonal ring gasket is matched with the flange groove, mainly manifested as surface contact. Compared with the elliptical ring gasket, although it is not easy to achieve a close fit with the flange groove, it can be reused and is easy to machine due to its straight section. The elliptical ring gasket is in line contact with the flange groove and has good sealing performance, but requires high machining accuracy, which increases manufacturing costs. At the same time, the elliptical ring gasket cannot be reused.

Execution standards for gaskets

GB/T 9130-2007;

JB/T 89-1994;

SH 3403-2013;

HG 20633-2009 (American System);

HG 20612-2009 (European System);

Shim features

1. High temperature and high pressure resistance, suitable for high-pressure flanges;

2. Durable and reliable sealing;

3. Adapt to the working conditions of variable load frequency;

Corrosion resistant products

Corrosion resistant low hardness metal ring gasket

Corrosion resistance low hardness metal ring gasket: Customized low carbon metal materials are used to adjust trace elements and change the ordinary heat treatment method to ensure the implementation of low hardness metal ring gaskets. The product is widely used in high-temperature and high-pressure equipment and static sealing parts of process pipelines in various industries such as petrochemical, chemical, metallurgical, refining, gas, nuclear energy, thermal power, etc.