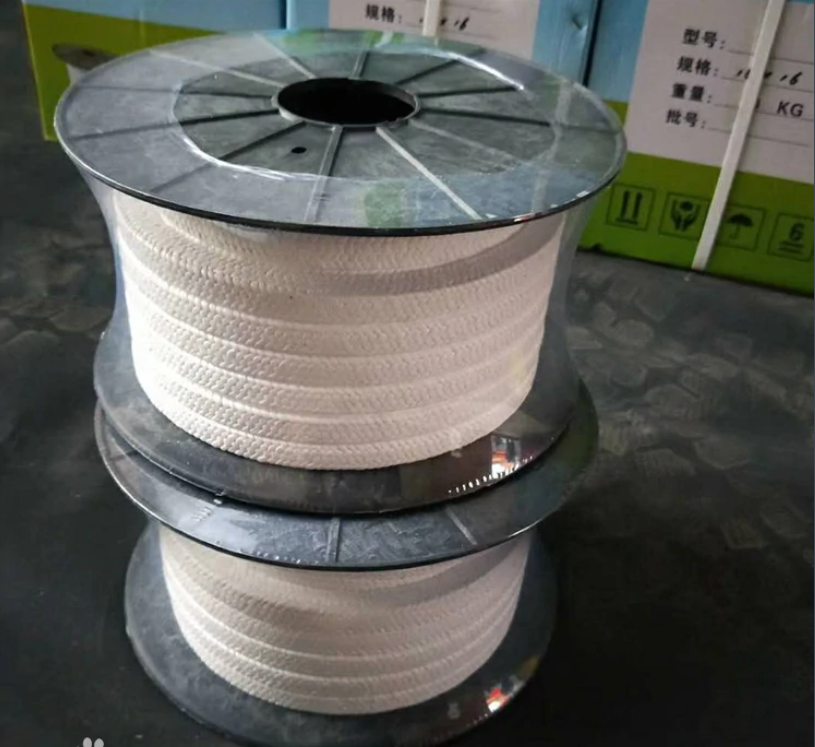

Items woven from pure polytetrafluoroethylene fiber with PTFE packing by weaving equipment

Teflon disc root is made of pure polytetrafluoroethylene fiber by knitting equipment, without treatment of PTFE lotion and lubricating grease. Due to its solid weave and flexibility, it is well matched with the shaft and stuffing box, exhibiting excellent corrosion resistance, good self-lubrication, and anti sticking properties. Can be used in chemical, food, pharmaceutical, papermaking, chemical fiber, fine chemical and other non polluting operating sites.

Chinese name: PTFE packing raw material: pure polytetrafluoroethylene fiber

catalogue

1. Chemical properties

2 types

chemical property

Tetrafluoro packing

Teflon disc root is made of pure polytetrafluoroethylene fiber without PTFE lotion and grease treatment. Due to its solid weave and flexibility, it is well matched with the shaft and stuffing box, exhibiting excellent corrosion resistance, good self-lubrication, and anti sticking properties. Can be used in chemical, food, pharmaceutical, papermaking, chemical fiber, fine chemical and other non polluting operating sites.

The PTFE woven (impregnated) packing is made of F4 raw material tape woven (impregnated) and shaped, with good chemical stability, good self-lubricating performance, and constant strength in high temperature and humid environments, making it easy to install, fill, and remove.

Service Limits

Project Item

Rotating pump

Reciprocating pump

Static sealing

Work pressure

Psi bar Kg/cm2

fifteen

one hundred

one hundred and fifty

Shaft speed M/s

four

two

Density g/cm3

one point three

Temperature ° C

-150~+260

PH range

0-14

Regular size STOCK Dimensions

Section size Sizemm

four

five

six

eight

ten

twelve

fourteen

fifteen

sixteen

eighteen

nineteen

twenty

About appr M/kg

thirty-five

twenty-two

sixteen

nine

five point six

three point nine

two point nine

two point five

two point two

one point seven

one point five

one point four

Purpose:

Used as sealing packing for various pumps and valves in industrial equipment.

type

Tetrafluoro packing can be divided into aramid interwoven black tetrafluoro packing, white tetrafluoro packing, aramid wrapped angle black tetrafluoro packing, oily black tetrafluoro packing, oil-free black tetrafluoro packing, cut wire tetrafluoro packing, and oily white tetrafluoro packing [1].

Firstly, the aramid interwoven black tetrafluoro packing is made of aramid fiber and black tetrafluoro as raw materials through a special process of mixed weaving. High strength aramid material is interwoven inside the packing, making the product more wear-resistant. It combines the excellent performance of aramid fiber and black PTFE fiber, making the product more wear-resistant and suitable for dynamic sealing at higher linear speeds and medium pressures. It can be used in industries such as chemistry, agricultural chemistry, petrochemicals, pharmaceuticals, sugar, papermaking, power, etc., as well as equipment such as reciprocating pumps, mixers, mixers, reactors, valves, etc. Suitable for water, sewage, oil, grease, weak acid and weak alkali solutions, acid-base solutions, and grinding media.

Secondly, the white tetrafluoroethylene disc root is woven from pure polytetrafluoroethylene fibers. It can be used in chemical, food, pharmaceutical, papermaking, chemical fiber, fine chemical and other non polluting operating environments, and is suitable for all chemical media except for soluble alkali metals and free fluoride ions.

Thirdly, the oily black PTFE packing is woven from PTFE wire containing graphite and anti corrosion lubricant. It has strong tensile strength and high thermal conductivity, while its low friction coefficient also gives it stability and long lifespan. It can be used for shaft sealing in industries such as food, medicine, papermaking, chemical fiber, and fine chemicals, as well as for sealing media such as water, steam, solvents, mixers, heat exchangers, and centrifugal pumps. Suitable for most media except for strongly oxidizing media.

Fourth: Oil free black PTFE packing is woven from polytetrafluoroethylene wire containing graphite particles.

Fifth: The cut wire PTFE disc root is woven from multiple strands of sintered and fully stretched PTFE wire, and fully impregnated in PTFE before being re impregnated during the weaving process. It has flexible features, dimensional stability, good compression resistance, anti extrusion, and high structural strength and density. It is one of the best packing materials for industrial applications. It is a universal packing that can be used in industries such as food, medicine, papermaking, chemical fiber, etc., especially high-pressure valves, plunger pumps, mixers, mixers, high peripheral speed shafts, rods, pistons, valves, expansion joints, and other equipment. Suitable for all chemical media except soluble alkali metals and free fluoride ions.

Sixth: The oily white PTFE disc root is woven from pure PTFE wire and treated with special lubricant silicone oil, which will not change its volume when used for a long time when the filling box has minimum pressure. Its low friction coefficient can prevent heating even on the surface of the shaft at high peripheral speeds. Suitable for mechanical sealing in corrosion-resistant media in high concentration and highly corrosive and oxidizing chemical products. It can be used in pumps, valves, and flange equipment that are not allowed to have pollution in the food industry, pharmaceuticals, papermaking, chemical fiber, and fine chemicals.